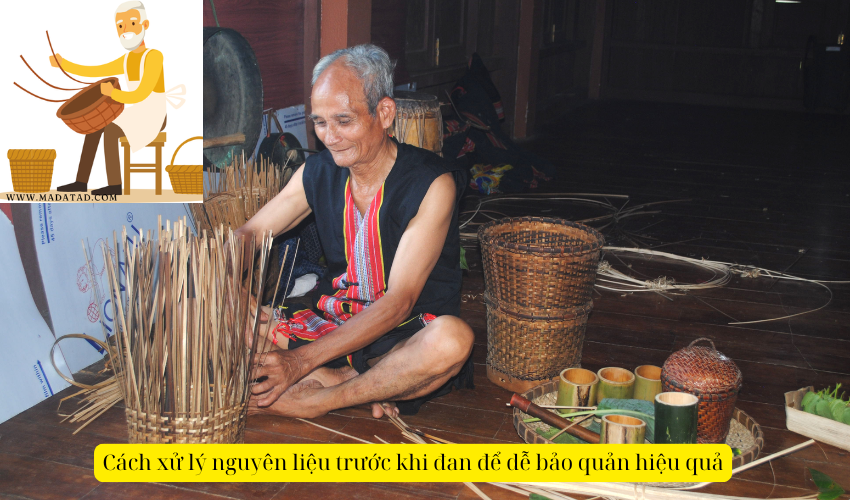

“Is it necessary to treat the material before knitting to preserve it effectively?” – This article will help you learn how to handle materials before knitting for easy and effective preservation.

Why is it necessary to process the material before knitting for easy preservation?

Ensuring product quality

Processing raw materials before packaging and storage helps ensure the quality of aquatic products. By removing impurities, washing and classifying ingredients, we can eliminate contaminants and keep products fresh and free from damage during storage.

Minimize losses

Processing raw materials before packaging also helps minimize losses during storage and transportation. By removing unnecessary parts and preparing ingredients carefully, we can ensure that products are not lost or damaged during the journey from the vessel to the point of sale.

Ensure food safety

Processing raw materials before packaging also ensures food safety. By using proper hygiene and material handling methods, we can ensure that seafood products are free from contamination or other harmful agents, keeping them safe from exposure to consumers.

Methods of processing raw materials before knitting

Wash ingredients

First, after harvesting, aquatic raw materials such as shrimp, fish, and squid need to be washed to remove mud, sand, and other impurities. This washing process helps remove impurities and ensures the hygiene of the raw materials before continuing with the processing and preservation steps.

Remove impurities and classify raw materials

After washing, it is necessary to remove impurities such as moss, crab shells, snail shells and remove bruised or poor quality fish. At the same time, it is necessary to classify raw materials according to size, type, and purpose of use, such as fish for export, fish for domestic consumption, or fish for fish sauce or animal feed.

Soak the ingredients in ice cold water

After removing impurities and classifying ingredients, seafood ingredients need to be soaked in ice cold water to quickly lower the temperature to about 0-2°C. Soaking this ingredient helps preserve it better and ensures long-term freshness for the product.

Advantages of processing raw materials before knitting

Ensuring product quality

Processing raw materials before catching helps ensure the quality of aquatic products. By removing impurities, washing and sorting raw materials, the final product will achieve better quality. This also helps increase commercial value and meet customer needs for fresh seafood products.

Increases preservation ability

The process of processing raw materials before catching also helps increase the ability to preserve aquatic products. By using ice and effective preservation methods, seafood ingredients can be stored for long periods of time while maintaining freshness and quality. This brings great benefits to the transportation and consumption of aquatic products.

Save time and effort

By processing raw materials before catching, the process of loading, unloading and transporting aquatic products also becomes easier. Sorting, washing and preserving raw materials before harvesting helps save time and effort in handling products after harvest.

This also helps increase production efficiency and minimize losses during transportation and storage of aquatic products.

Preserve raw materials after processing

Preserve shrimp after processing

After receiving and processing shrimp, the shrimp preservation process needs to be carried out carefully to ensure food quality. Shrimp after being soaked in ice water should be stored in an insulated barrel or tank capable of maintaining the necessary cold. Checking the temperature and changing the ice regularly is very important to ensure the shrimp does not spoil and stays fresh for a long time.

Preserve fish after processing

After processing and sorting, fish should be placed in plastic trays or insulated containers according to the mentioned process. Ensuring temperature during storage is very important, and periodic checks to ensure stable temperatures are necessary. In addition, sterilization and cleaning measures after storage also need to be implemented to ensure food safety.

Preserve ink after processing

After processing and soaking in ice cold water, the squid should be wrapped in polyethylene bags and placed in insulated containers. Making sure the ink doesn't rub together and cover the top with ice is very important to ensure preservation quality. In addition, checking and maintaining temperature during storage also needs to be done properly.

Preservation measures after processing aquatic raw materials need to be carefully implemented to ensure food quality and safety.

The importance of processing materials before knitting

Processing raw materials before knitting is an important step in the seafood preservation process. Removing impurities, washing and classifying ingredients helps ensure food quality and consumer safety. In addition, the raw material processing process also helps enhance the ability to preserve and transport seafood effectively.

Advantages of processing raw materials before knitting:

- Ensuring safe food: Removing impurities and washing ingredients helps eliminate microorganisms and harmful agents, ensuring food safety for consumers.

- Enhance preservation ability: Classifying and stacking raw materials in appropriate preservation methods helps increase the ability to store seafood for a long time without reducing product quality.

- Ensuring commercial quality: Removing poor quality fish and classifying them according to intended use helps ensure the quality and economic value of the final product.

The process of processing raw materials before weaving plays an important role in the seafood preservation process, especially when products need to be transported to consumption locations. Proper implementation of raw material handling procedures will ensure food quality and safety, thereby creating consumer trust and expanding consumption markets for aquatic products.

How to process materials before knitting for each type of material

Preserving shrimp

– Receive raw shrimp and remove impurities, trash, sand, and bruised or poor quality shrimp.

– Wash the shrimp to remove microorganisms that decompose fish meat and immediately soak in a bucket of ice water to quickly lower the shrimp temperature to 0-2°C.

– Preserve shrimp by placing it in an insulated container, making sure not to stack the shrimp in layers that are too thick to avoid the shrimp being crushed and losing weight.

Preserving fish

– Remove impurities, process and wash immediately after harvesting fish to ensure commercial quality.

– Arrange fish in plastic trays in layers and rows, spread ice evenly on the trays for preservation.

– For preservation method using insulated containers, it is necessary to check the temperature and add ice when necessary to maintain the necessary coldness.

Preserving ink

– Wash off mud, sand and dirt from squid after catching.

– Soak the squid in a bucket of ice water for about 10-15 minutes to quickly lower the squid temperature to 0-2°C.

– Preserve squid by wrapping the squid in polyethylene bags and placing them in boxes in order, one layer of ink, one layer of ice.

These paragraphs provide specific instructions on how to handle and preserve different types of seafood before processing. The information is credible as it follows industry standards and best practices for handling and preserving seafood.

The material needs to be processed before knitting and is not required

Materials that need to be processed before knitting:

– Shrimp: need to remove impurities and wash to eliminate most microorganisms that decompose fish meat.

– Fish: need to remove impurities, trash, sand, remove bruised or poor quality fish, wash to eliminate most microorganisms that decompose fish meat.

– Squid: need to remove all dirt, sand, moss, crab shells, snail shells, wash off mud, sand and dirt.

Materials that do not need to be processed before knitting:

– Ice: used to preserve seafood ingredients, you need to use flake or crushed ice, do not use monolithic ice or lump ice.

– Gloves and labor protection gear: need to be used to ensure safety during the handling of aquatic raw materials.

– Soap, chlorine water: need to be used to clean and disinfect tools after handling aquatic ingredients.

The materials that need to be processed before knitting involve removing impurities and washing to ensure food safety and commercial quality. The materials that do not need to be processed before knitting are all necessary tools and supplies in the process of processing aquatic materials.

Simple and effective material handling

Remove impurities, process, wash

Immediately after harvesting, it is necessary to remove impurities, trash, sand and fish that are bruised or of poor quality. Large fish should be gutted and washed to remove most of the microorganisms that decompose fish meat.

How to arrange fish for preservation

- Arrange fish in a tray: use a fish/ice ratio of 1/1, place fish in a plastic tray with a layer of ice on the bottom and top, ensuring convenience and safety.

- Arrange the fish in an insulated box: use a fish/ice ratio of 1/1, put the fish in an insulated box with a thick layer of ice underneath, do not put the fish in too thick layers to avoid the fish being crushed.

- Pile the fish in the compartment: use a fish/rock ratio of 1:1, cover the bottom of the fish compartment with a thick layer of ice, then pile the fish into thin layers to prevent the fish from being crushed and to be protected by the surrounding rocks. .

Common mistakes when not processing the material before knitting

1. Does not remove impurities and impurities

Failure to remove impurities such as moss, grit, crab shells, snail shells… before preserving seafood can lead to seafood being damaged or losing quality. These impurities can speed up the decomposition of food and reduce the freshness of seafood.

2. Not classifying ingredients

Failure to classify seafood by size, type and quality can lead to ineffective storage. Aquatic products with high economic value such as prawns and tiger prawns need to be classified and preserved separately to ensure quality.

Benefits of applying material processing methods before knitting

1. Ensure product quality

Removing impurities, processing and washing immediately after harvest helps ensure food quality. Microorganisms that decompose fish meat are eliminated, helping the product not go rancid and ensuring food safety. Besides, classifying and processing raw materials before preservation also helps increase the attractiveness and preserve the natural flavor of seafood.

2. Save time and effort

By sorting and processing raw materials immediately after harvest, the storage and transportation process becomes easier. Removing impurities and classifying raw materials right from harvest helps save time and effort during later storage and processing.

3. Enhance commercial value

By applying the method of processing raw materials before knitting, aquatic products will have higher economic value. Strictly classifying, processing and preserving raw materials helps increase commercial value and attract consumers.

Processing raw materials before knitting helps ease preservation and increases product life. This is especially important in ensuring food quality and safety.